MATERIALS

1. Zirconium Oxide --- Zirconium Oxide material has the advantage of high toughness and high bending strength, good thermal expansion coefficient, high impact resistant, Its superior performance close to the advantages of steel. So it widely used in electronics, machinery, aerospace, petrochemical and other fields.

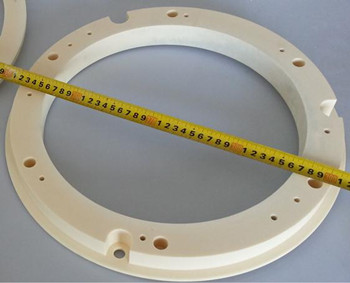

Zirconium Oxide

Zirconium Oxide material has the advantage of high toughness and high bending strength, good thermal expansion coefficient, high impact resistant, its superior performance close to the advantages of steel.

Zirconium Oxide widely used in mechanical seal and ball mill medium, cutting tools, ceramic bearing, automobile engine parts, paper machine dehydration equipment, etc. The wear resistance of zirconia ceramics is 15 times the size of alumina ceramic, zirconia ceramic friction coefficient is only half of the alumina ceramic, and alumina ceramic friction coefficient is very low.

Zirconium Oxide ceramics form Method including: dry press forming, isostatic pressing molding, grouting, hot die-casting molding, cast molding, injection molding, plastic extrusion, colloidal forming of solidification etc. The most widely used form methods are injection molding and dry pressing.

Property of Zirconium oxide ceramics

1. High density

2. High corrosion resistance.

3. High strength and high fracture toughness.

4. High hardness and excellent wear resistance.

5. High temperature resistance ability.

6. Low thermal conductivity.

Uses for Zirconium Oxide

1. Ceramic Rods & Tubes

2. Abrasion resistant tube and liners

3. Sanding machine accessories

4. Ceramic seal rings

5. Instrumentation thermal ceramic parts

6. Electrical insulators

7. Motor ceramic shaft

8. Precision ceramic plate

9. Thermometry sensors

10.Other machinable ceramic

2. Aluminum Oxide ---Aluminum Oxide ceramic is the most widely used advanced ceramic material. It has the advantage of good insulation good chemical corrosion resistance and melting properties, small thermal expansion coefficient, mechanical strength, good thermal conductivity characteristics. Alumina ceramics is mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on.

Aluminum oxide ceramics is an alumina (Al2O3) as a main component a ceramic material; it divided into high purity type and ordinary type

two kinds. High purity alumina ceramic is Al2O3 content in more than 99.9% of the ceramic material, due to its high sintering temperature

1650-1990℃, the transmission wavelength of 1 ~ 6μm. Use of its light transmittance and resistance can be used as the alkali metal

sodium lamp; used as a high-frequency integrated circuit substrate and the insulating material in the electronic industry.

The Ordinary type including 99%,95% 90%,85% 75% alumina etc. Such aluminum oxide Used as refractory material and or make

wear-resisting corrosion resistance of parts. Aluminum oxide ceramics is the most widely used advanced ceramic material. its form Methods

including: dry press, grouting pressure, extrusion molding method, cold isostatic pressing, injection, stretch film, hot pressing and hot isostatic

pressing molding, a variety of methods.Aluminum oxide ceramics is mainly used in biological ceramic, wear resistant materials such as ceramic

ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe,

electronic devices such as high voltage switch tube shell insulation material and so on.Application of Aluminum Oxide

1.Ceramic substrate

3. Abrasion resistant tube and liners

5. Ceramic seal rings and valve

6. Electrical insulators

7. Ceramic tube

8. High temperature protect ceramic tube

9. Ceramic ballistic

10.Ceramic sanitary Car or machine thermometry sensors

11. Instrumentation thermal ceramic parts

12. Medical ceramic parts

13. Ceramic sanitary

Property of Aluminum Oxide

1. Aluminum Oxide offers good thermal conductivity

2. High temperature capabilities

3. Wear-resistant, very hard

4. High strength and stiffness

5. Resistant to strong acid & alkali

6. Excellent dielectric properties from DC to GHz frequencies

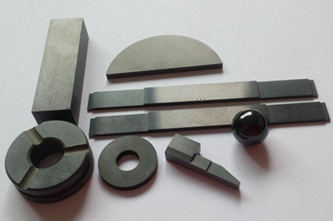

3.Silicon carbide----Silicon carbide ceramic has excellent mechanical properties, such as high flexural strength, excellent oxidation resistance, good corrosion resistance, high abrasion resistance and low coefficient of friction. It widely used in aerospace, nuclear power, bio-medical, military, defense and automotive applications that require exceptional heat resistance or insulation, wear and corrosion resistance.

Silicon carbide ceramic has excellent mechanical properties, such as high flexural strength, excellent oxidation resistance, good corrosion resistance, high abrasion resistance and low coefficient of friction. Especially its high temperature mechanical properties (strength, creep resistance etc.) are the best known ceramic material. its high-temperature strength can be maintained until 1600 ℃, Its antioxidant activity is all the best in non-oxide ceramics.

The disadvantage of silicon carbide Ceramic is that the fracture toughness is low, namely brittle is relatively large.

silicon carbide are high-performance ceramic parts used in aerospace, nuclear power, bio-medical, military, defense and automotive applications that require exceptional heat resistance or insulation, wear and corrosion resistance

Application of silicon carbide ceramic

· Grinding material

· Refractory material

· Wear resistant parts, such as cylinder liner

· High temperature application.

· Powerful of anti-acid, anti-alkali, anti-corrosion

· Military applications, such as ceramic ballistic.

· Electrical applications,

· Heat treatment, heat exchanger

· Chemical industry, seal ring or bearing etc.

Property of silicon carbide

- 1. High hardness

- 2. Good creep resistance.

- 3. Good corrosion resistance

- 4. Oxidation resistance

- 5. Small thermal expansion coefficient

- 6. High thermal conductivity

4. Silicon Nitride Ceramic---- Silicon nitride ceramic with very high strength, especially the hot-pressing silicon nitride, it is one of

the hardest substance in the world. It is extremely resistant to high temperature, its intensity can be maintained until the high temperature of 1200 ℃ without fall. it can not melt into melt body, until the temperature reached to 1900 ℃ to decompose.

Silicon nitride has amazing chemical corrosion resistance, it is resistant to almost all inorganic acids and caustic soda solution 30% or less, it also resistant to many organic corrosion. At the same time, Silicon nitride is also a kind of high-performance electrical insulating materials.Silicon nitride with very high strength,especially the hot-pressing silicon nitride, it is one of the hardest substance in the world. It is extremely resistant to high temperature, its intensity canbe maintained until the high temperature

of 1200 ℃ without fall. it can not melt into melt body, until the temperature reached to 1900 ℃ to decompose.Silicon nitride has amazing chemical corrosion resistance, it is resistant to almost all inorganic acids and caustic soda solution 30% or less, it also resistant to many organic corrosion. At the same time, Silicon nitride is also a kind of

high-performance electrical insulating materials.Silicon nitride is a kind of super hard material, It itself has a self lubricating effect and wears resistance; except hydrofluoric acid, it does not react with other inorganic acid, strong corrosion resistance, high temperature oxidation

resistance. And it also can resist cold and hot shock, in air heated to above 1000 ℃, a sharp cooling heating sharply

again, also won't fracture.Application of silicon nitride ceramic

· Ceramic valve ball in oil field

· High-temperature support material

· Cutting tool in Mechanical processing industry

· Motor application, ceramic impeller etc

· Powerful of anti-acid, anti-alkali, anti-corrosion

· Thermocouple protect tube

· Semiconductor ceramic parts.

· Refractory material in Metallurgy area.

· Chemical industry, seal ring or bearing etc.

- 1. High thermal stability

- 2. Good antioxidant ability

- 3. Good creep resistance in high temperature.

- 4. Very hard and High mechanical strength.

- 5. High wear resistance.

- 6. Stability Chemical performance.

- 7. Low density, small specific gravity, good electric insulation

MATERIALS

Contact Us

Name: Linda Huang

Tel: +86-512-66255075

Fax: +86-512-66255030

Mobile: +86-18550512237

E-mail: [email protected]

Skype: smkceramic

MSN: [email protected]

QQ: 836574060

WeChat: 18550512237

Whatsapp: 8618550512237

Add: 11-8 Xiangshan Li,No.8 Gucun Road,Xukou Town,Wuzhong district.Suzhou City,China.

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online